- Home

- By Industry

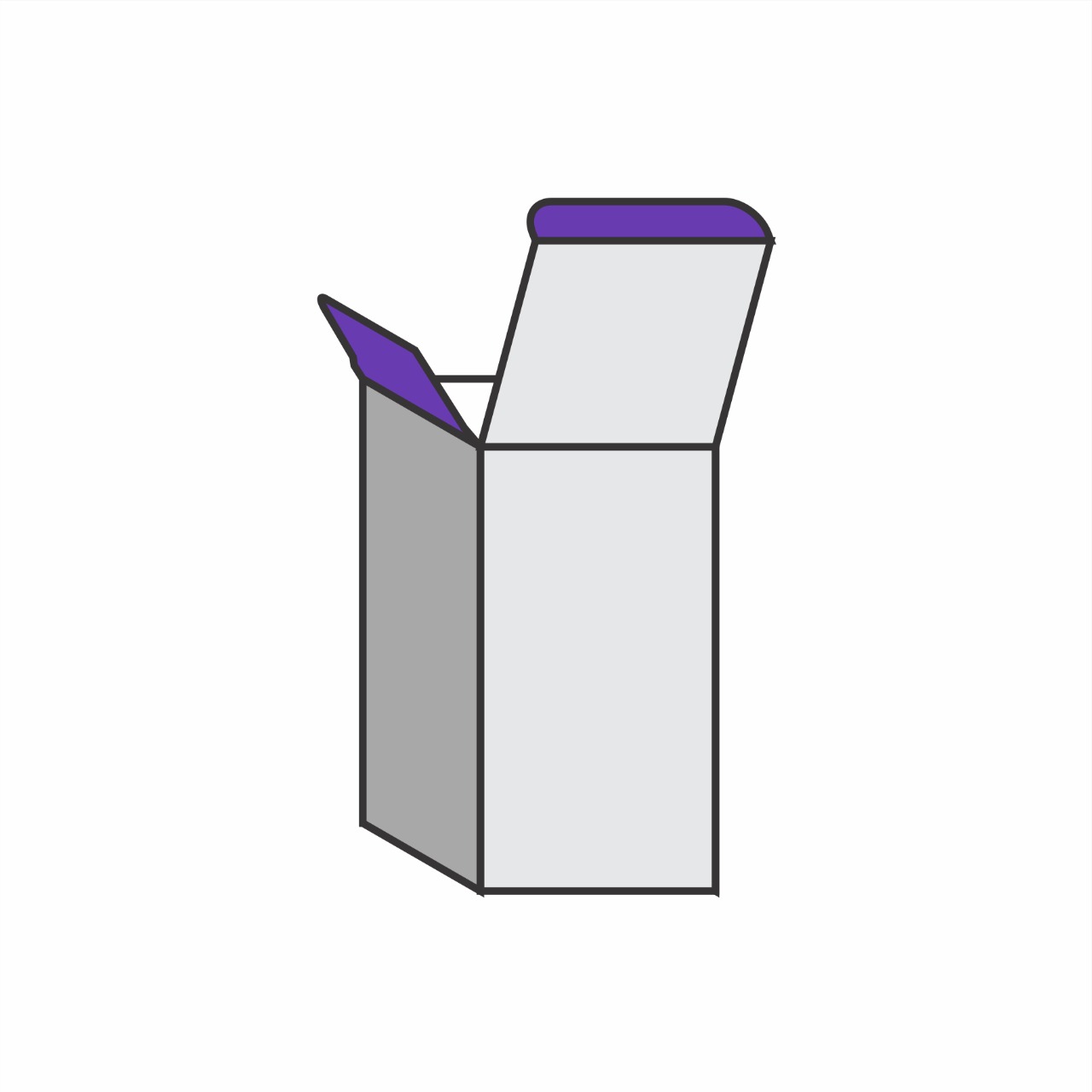

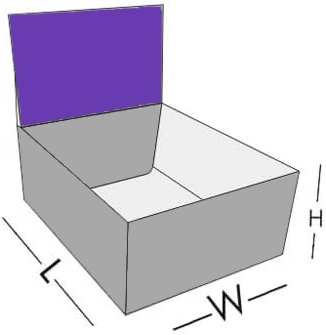

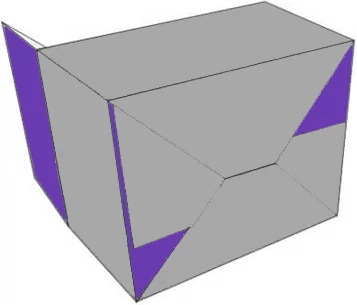

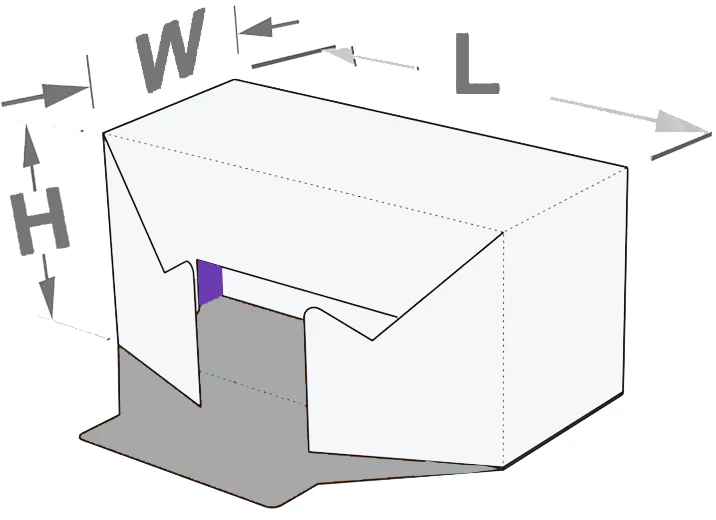

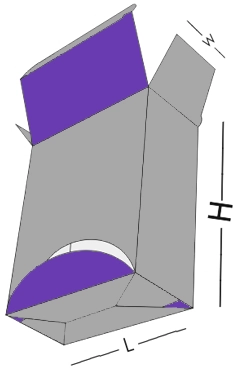

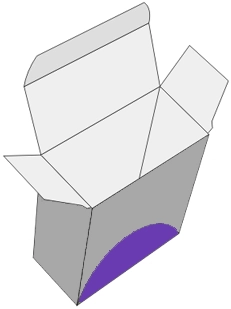

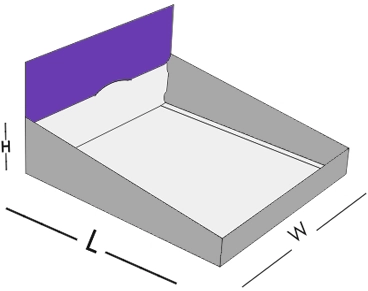

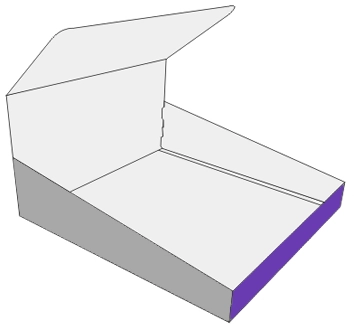

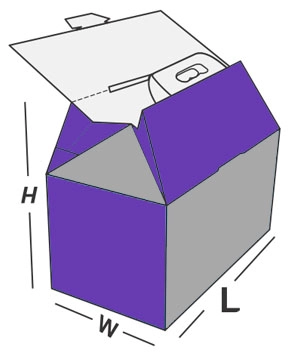

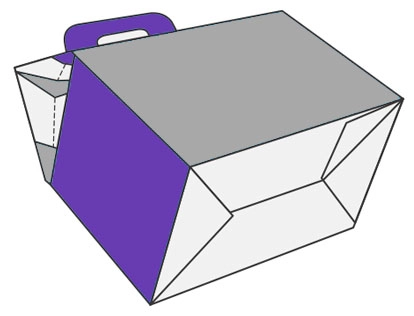

- Box Style

- Other Products

- Design Service

- Deals

- Get Instant Quote

At Custom Packaging pro – we strive to enhance your image

-

No Die and Plate charges

-

6-8 Days turn around

-

High Quality Offset Printing

-

Starting From 100 Boxes

-

In House Design Support

-

Request Free Template

-

FREE Shipping

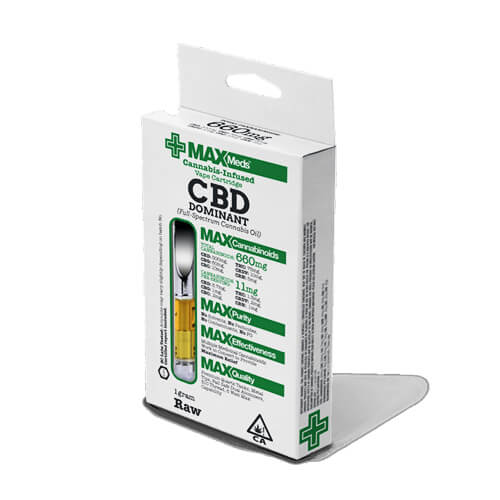

BY INDUSTRY

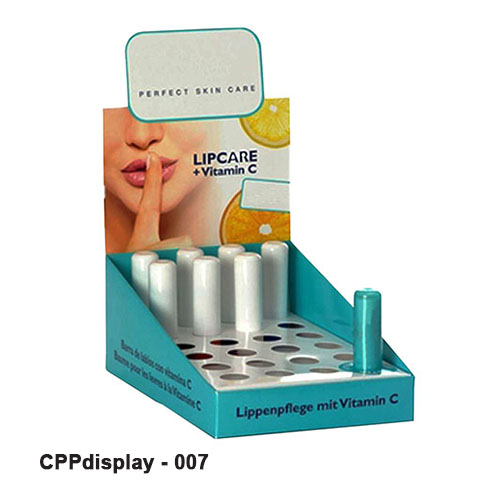

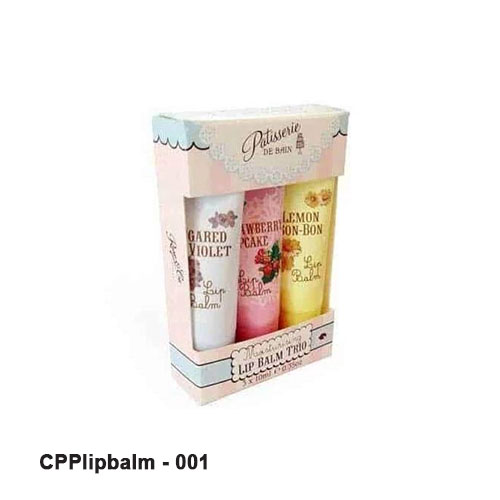

Offering Custom Packaging Boxes with Logo

CPP provide you the best experience as they elevate your products with our exquisite Custom Packaging Boxes with Logo- where creativity meets cardboard, and your brand's story gets a captivating new chapter!

By Industry

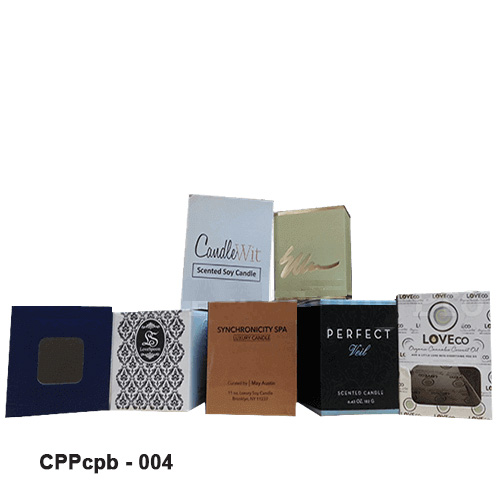

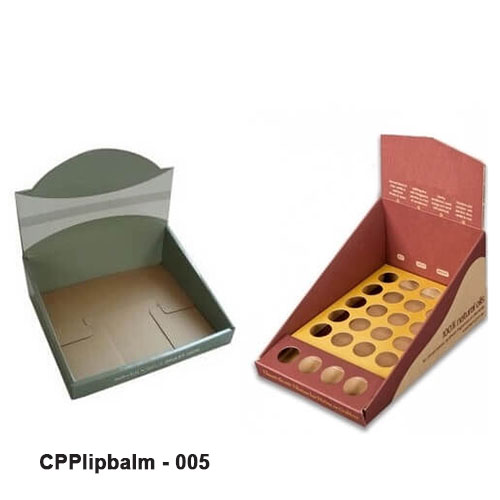

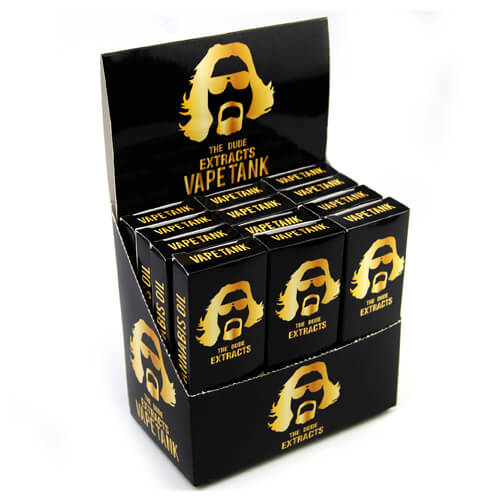

BY BOX STYLE

By Box Style

Custom Packaging Pro- a Company delivering excellence in product packaging

Trusted By 5000+ Clients

Custom Packaging Will Address the Particular Product Requirements

In a highly competitive market, where initial impressions hold substantial importance, these boxes assume a pivotal function in attracting the attention of prospective purchasers. Boxes are a flexible and necessary part of contemporary packaging solutions. Custom Packaging to fit particular specifications and address the requirements of various goods and sectors. These boxes are vital to today's commercial environment, serving as both a means of safeguarding delicate things during transportation and boosting the aesthetic appeal of retail merchandise. This implies they can precisely suit the product's proportions, whether for display or protection.

By carefully designing and implementing Custom Packaging, businesses can differentiate themselves from competitors and create a memorable journey for their customers, fostering brand loyalty and long-term success. As businesses continue to adopt sustainable practices, Printed Packaging will play a vital role in shaping customer perceptions and driving sales. So, they will make products accessible and safe. The usage of these creative designs, stylish colors, inspirational features, and superb quality Custom Boxes not only enhances the beauty of the brand but also increases product sales.

Enhance the Safety Concerns by Using Custom Boxes

The capacity of boxes to offer a customized packing solution is one of its main benefits. Custom Boxes can remain perfectly designed and built, unlike off-the-shelf boxes. This tight fit minimizes waste and lowers shipping costs, in addition to guaranteeing the product's safety throughout transit. The utilization of these boxes has emerged as a fundamental component within the realm of business and marketing. These multifunctional containers fulfill various roles, including safeguarding merchandise during transportation and augmenting brand recognition and customer satisfaction. This Packaging, plays a crucial role in the consumer product business.

As consumers continue to seek authenticity with products they purchase, the allure of Custom Boxes is likely to endure, perpetuating the tradition of them for years to come. By investing in Custom Packaging Boxes, businesses can take their brand to new heights, while customers can enjoy an unparalleled experience that leaves a lasting impression.

Retail Boxes Help Creating Unique and New Styles

One of the principal purposes of boxes is to protect the commodities they enclose. Proper packing can mitigate damage that may occur during the transportation and handling process. Boxes remain helpful for various products because they are available in different sizes and shapes. Depending on the requirements of the product and the aesthetic preferences of the brand, they come in various styles. Apart from their practical advantages, Retail Boxes have a distinctive branding prospect. This packaging also plays a significant role in supporting sustainability initiatives, as numerous companies choose to utilize environmentally friendly materials and designs.

Imprint Attractive and Engaging Slogans on Printed Boxes

Companies can use these boxes to help clients have an unforgettable unwrapping experience while reinforcing their brand identity. Companies may imprint their slogans, logos, and product details directly onto Printed Boxes with custom printing options, which helps to establish a strong brand presence and leave a lasting impression. This Packaging solution enables firms to customize boxes that are precisely tailored to accommodate their products, thereby mitigating the potential hazards of breakage, spills, or deformation. These boxes function as a medium for expressing and representing brand identity. These boxes come to match your exact specifications.

Customize Boxes Create Buzz to Maintain Captivating Images

Boxes are useful for more than just packaging; they can serve as marketing aids. Customize Boxes often come by companies to launch new goods, hold exclusive sales, or commemorate occasions like holidays and festivals. To draw clients and create buzz about the product or campaign, these boxes remain safe using captivating imagery and wording. In addition to yielding cost savings regarding returns and replacements, this practice also contributes to establishing a favorable image characterized by high standards of excellence and dependability. The visual elements such as design, color scheme, and logo incorporated in the packaging facilitate brand recognition and recall among customers.

Show the Company’s Communication Skills because of Product Boxes

Boxes may also be ecologically beneficial. Product Boxes can be made using Eco-friendly inks and recyclable materials, examples of sustainable Packaging alternatives that support a brand's environmental responsibilities. This shows a company's commitment to sustainability and appeals to customers who care about the environment. Establishing uniformity in branding across all packaging materials is pivotal in cultivating brand loyalty and trust, as buyers develop an association between the brand and a specific standard of excellence and dependability.

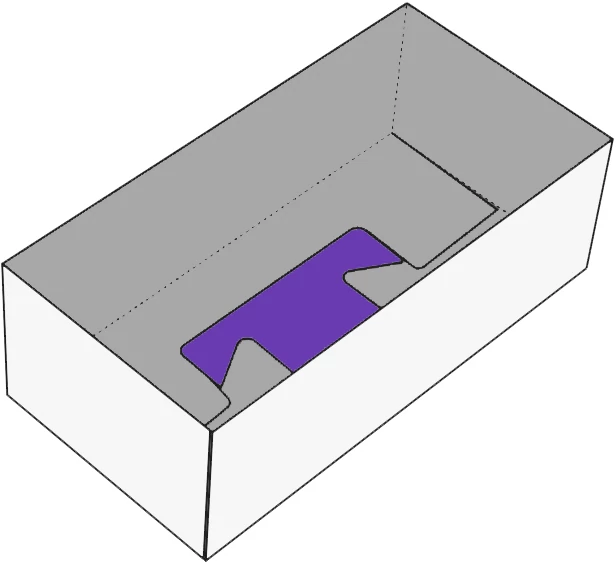

Packaging Boxes Will Safeguard Breakable Objects during the Transit

Boxes are essential to e-commerce as well. Packaging Boxes have grown in importance as a component of the customer experience with the development of Internet shopping. To safeguard breakable objects in transit, they may have components like dividers, inserts, and cushioning materials. Organizations can utilize these boxes to effectively communicate their distinct message and establish an enduring impact on their clientele. To thrive in the current highly competitive market, businesses must acknowledge the significance of packaging and utilize it to augment their product presentation and establish a strong brand identity.

Match the Subscription Box Services with Retail Packaging

To build excitement and anticipation among subscribers, many services rely on distinctive and eye-catching packaging. Retail Packaging can have content specifically tailored to improve the overall experience and can be made to match the subscription's theme. Additionally, these boxes are a necessary component of subscription box services. These boxes also provide a significant possibility for narrative development. Businesses can effectively engage customers and establish a connection by incorporating product information, usage directions, or the company's history on the packaging.

Printed Packaging Will Help Modern Enterprises Succeed

Boxes are an essential and multipurpose component of the packaging business. Printed Packaging provides customized solutions for companies who want to safeguard their goods, establish a powerful brand identity, and provide clients with an unforgettable unboxing experience. Numerous advantages that these boxes offer help modern enterprises succeed. In today's cutthroat industry, their ability to blend sustainability, branding, and practicality makes them a priceless asset. These packaging boxes are made to endure the rigors of transportation while guaranteeing that the item will arrive undamaged.

Custom Printed Packaging offer benefits, including product protection and sustainability. In addition, businesses need to know how to leave a lasting impression on customers while looking for exciting experiences. Therefore, when you use these Custom Printed Packaging Wholesale Products, this will assist your company in climbing to the top of the list. For the safety of your product in the transit phase, you need to consider Packaging for your brand. Your product will be standout in the crowd if you get Packaging Box for your brand because it makes your product look desirable.

Stay Compatible to Perform Functions with Custom Size Packaging

Narrating the narrative behind a product or presenting its Eco-friendly attributes can strike a chord with consumers who prioritize environmental sustainability, distinguishing the brand from its rivals. Boxes are essential to the business sector. Custom Size Packaging does more than merely hold goods; they are protective measure, practical marketing tool, and channel for disseminating crucial product information. Whether you run a business or are a consumer, you have probably seen these boxes in various sizes and forms, each intended to serve a specific function.

Custom Size Boxes Lower the Possibility of Returns

The protection of the products they contain is one of their primary purposes. Custom Size Boxes can guarantee that the item reaches its intended location undamaged. This protection includes guarding against exterior elements, including moisture, dust, and collisions while in transportation. On the other hand, Stores and customers need to know this information. Companies spend time and money creating packaging for their items that offers the best protection possible, lowering the possibility of returns or unhappy customers because of defective merchandise. They fulfill the role of safeguarding items, functioning as marketing instruments, and embodying the essence of brand representation.

Identify the Identity and Core Values with Boxes Wholesale

By using distinctive images, logos, and messaging, companies may leave a lasting impact on their clientele. Boxes Wholesale is an effective marketing tool and provides goods protection during transit. In addition to safeguarding merchandise and communicating brand image, these packaging containers play a role in supporting marketing initiatives. Visually appealing and captivating packaging can arouse the curiosity of prospective consumers and motivate them to select a particular product from among the available display options. These boxes also make a significant contribution to sustainability initiatives.

Customers enjoy the designing of the products that give them a classy and elegant look. These Boxes Wholesale help in promoting the products. These features make Boxes stand out, giving them a distinctive appearance. However, they can bring your goods to life and give customers a distinctive visual experience. Boxes are the premium choice for customers. They can have a significant appeal that attracts clients. Additionally, Custom Packaging solutions ensure that your product meets the needs of your customers and its return policy. This packaging will perform all function for your brands.

Wholesale Packaging is a means to encase products. It's a statement of sustainability, durability, and authenticity. Its Eco-friendly nature aligns with the growing demand for environmentally responsible practices. From their meticulously crafted exteriors to the sensory pleasures they evoke, Wholesale Boxes enrich the journey and cherish prized possessions. Businesses have embraced the trend of these boxes.

Learn How Do Wholesale Boxes Improve User Experience

Boxes provide crucial details about the merchandise. Wholesale Boxes cover the product's features, how to use it, the ingredients, and any safety alerts. Consumers depend on it to help them make well-informed purchases, and retailers require it to follow the rules and guarantee that merchandise is handled and stored correctly. Customer trust may be developed, and the overall user experience improved with clear and straightforward information on the box. By utilizing a meticulously created box, enterprises can effectively convey the distinctive attributes that set their items apart from competitors.

Wholesale Boxes deliver the best appeal to the products. They can elevate the advertising and marketing of the products. The Boxes are elegant and classy in looks and attract the customers of the markets. Moreover, these boxes help in increasing sales and revenues. The Custom Printed Boxes help in generating revenues for the brands by increasing sales. Moreover, these boxes have great looks that attract customers.

Wholesale Packaging Becomes Economical Solution for Businesses

Another noteworthy feature of these boxes is customization. Companies frequently modify the shape and dimensions of their packaging to meet their unique requirements. Brands may match their packaging to their identity through customization, projecting a recognizable and consistent image. Additionally, Wholesale Packaging enables businesses to find economical solutions by optimizing the size and form of their boxes to save wasteful material usage and shipping expenses. Whether for retail displays or online shipping, these boxes improve consumer satisfaction and help build brand awareness and loyalty.

Support Sustainable Approach and Social Objectives Using Packaging Wholesale

One valuable and essential component of packing solutions is boxes. Packaging Wholesale comes to fit particular product specifications and branding demands. They are perfect for various industries, including food and cosmetics, because they are available in various sizes, shapes, and materials. In addition to appealing to customers who care about the environment, sustainable packaging supports business social responsibility objectives. These boxes exhibit a wide range of shapes and sizes, extending beyond the confines of traditional dimensions. They assume a substantial function in marketing and customer experience, thereby creating a lasting impact on consumers.

Custom Boxes with Logo Will Strengthen Brand Identification

Flexibility in design and customization is provided, enabling firms to develop packaging that is consistent with their brand's identity and appeals to their intended consumer base. Boxes have become even more crucial in the era of online shopping. Custom Boxes with Logo will perform functions beyond just a means of delivering goods to consumers. Many e-commerce companies now use their logos and designs in their packaging, making these boxes an extension of their online presence. Customers get a better unwrapping experience as a result, and it also strengthens brand identification online. This packaging has a dual purpose beyond its practical function as a container.

Transmit Important Information because of Custom Packaging Boxes

The function and significance of boxes in influencing the consumer experience and fostering corporate success will change as the retail environment does. In the retail industry, Custom Packaging Boxes are anything but typical, regardless of whether you are a customer or a business owner. These boxes are a complex part of contemporary trade. In addition to offering protection, they also function as marketing tools to transmit essential information. The range of design possibilities spans from sleek and minimalist styles to vivid and fun aesthetics, offering many options. They will allow for customization and support sustainability initiatives.

Customize Packaging Offer Delivering a Useful Answer

Businesses are always looking for ways to differentiate themselves in the crowded market of today, and this packaging offers a helpful answer. Customize Packaging, which has several advantages for both producers and customers, is an essential component of contemporary company operations. This strategy entails customizing packaging's appearance, composition, and use to suit the unique requirements and tastes of a particular brand or product. In addition, enterprises can select ecologically friendly materials and printing alternatives to attract consumers that prioritize environmental sustainability.

Associate with a Favorable Experience Using Customized Boxes

Brand recognition is one of the packaging's main benefits. Having distinctive and one-of-a-kind packaging can help a product or brand stand out to customers in a congested market. Increased repeat business and consumer loyalty may result from this acknowledgment. Customers are more inclined to select a product with Customized Boxes associated with a favorable experience than one that has generic packaging when they see it. One additional significant benefit of these boxes is the aspect of personalization. Businesses can customize packaging for various occasions.

Wholesale Custom Packaging Will Target Your Desirable Audience

Companies may successfully communicate their corporate identity and tell their story using this packaging. Wholesale Custom Box Packaging will reflect an organization's beliefs and mission using unique designs, colors, and logos. A company's intended message to its target audience is reinforced, and a strong brand image is established thanks to this branding consistency. Incorporating personalized elements, such as customized messages, has the potential to cultivate a lasting impression among customers and enhance their affinity towards the business. They possess the potential to exert a significant impact on consumer purchasing behavior and shape the overall perception of a brand.

Enhance Functionality to Boost Value with Custom Boxes Wholesale

Packaging can raise a product's perceived worth. Even if the product inside is identical to that of competitors, well-designed and produced packaging can give a product an air of exclusivity and luxury. Profitability can rise, and higher price perceived value can justify higher price points. Custom Boxes Wholesale can enhance functionality in addition to perceived value and brand recognition. This not only caters to consumers who prioritize environmental concerns but also coincides with the objectives of corporate social responsibility. These boxes are an effective technique that provides companies with several advantages.

Wholesale Custom Boxes Develop Enjoyment of the User

Packaging can be customized to match particular products and industries. For the safety and enjoyment of the user, Wholesale Custom Boxes is crucial that items come correctly and appropriately for the application for which they are intended. There is a growing recognition among customers regarding the ecological consequences associated with packing materials. Business enterprises can select environmentally sustainable materials, such as recyclable cardboard or biodegradable polymers, for their packaging solutions. These boxes provide applicable value that might simplify processes and cut expenses.

Perfectly Fit within Environmental Ideas with Customized Packaging

Nowadays, many companies are aware of their influence on the environment and look for environmentally friendly packaging options. Customization enables businesses to use environmentally friendly materials and create waste-efficient packaging designs. Customized Packaging could potentially increase the customer base because it not only fits with environmental values but also appeals to environmentally conscious consumers. For instance, to preserve freshness, food products would need to be packaged with airtight sealing, while products might need to be packaged with shock and static electricity protection.

Packaging with Logo Will Provide Unbeatable Product Benefits

Packaging offers a flexible marketing tool to firms. Special events, limited-edition releases, and seasonal promotions can all be emphasized with distinctive packaging designs. Because of this adaptability, businesses can consistently draw in customers and increase sales by keeping their product packaging exciting and engaging. Packaging with Logo possesses many applications and serves many purposes within contemporary business and marketing contexts. Packaging has multiple functions in the business context, including safeguarding items, communicating corporate identity, augmenting marketing endeavors, and supporting environmental initiatives.

Adopt Flexible Marketing Tools Using Printed Boxes Wholesale

Companies can create packaging that precisely fits their goods, lowering the possibility of damage occurring during storage and transit. Printed Boxes Wholesale can reduce product loss and returns, resulting in savings. Additionally, its packaging is Eco-friendly. In addition to supporting industry-specific needs and promoting sustainability, it facilitates brand awareness, communicates brand identity, raises perceived value, and functions as a flexible marketing tool. As enterprises increasingly acknowledge the significance of packaging in influencing client impressions and stimulating sales, utilizing these boxes will persist as a crucial component of their strategic approach.

Protect the Internal Product Using Custom Printed Boxes Wholesale

The success of a business can be significantly impacted by investing in this packaging in a market that is becoming more and more competitive. It's not only about safeguarding the internal product; it's also about giving the customer an experience they will remember and find significant. Custom Printed Boxes Wholesale is a crucial component of contemporary business tactics. Investing in well-designed and environmentally sustainable packaging can result in heightened consumer happiness, enhanced brand awareness, and, ultimately, enhanced competitiveness within the market. This leads to a consistent and unforgettable consumer experience and improves cognition.

Wholesale Printed Boxes Will Increase Branding Potential

A crucial part of the contemporary business environment is packaging. It acts as a liaison between producers and buyers, guaranteeing that goods are presented attractively and are safe for transportation. In this regard, Wholesale Printed Boxes have become a handy and adaptable instrument for companies of various kinds and sectors. These boxes are a popular option for companies looking for customized packaging solutions since they provide several advantages, including increased branding potential and sustainability benefits. Including customizable branding options enables firms to display their logos, product information successfully, and other branding aspects.

Leads to a Consistent Experience with Custom Packaging Boxes Wholesale

The ability to complement a brand's identity and messaging is one of its main benefits. Custom Packaging Boxes Wholesale may be made in any size, shape, or color. Companies can develop packaging that perfectly captures the essence of their distinct brand. These boxes give businesses a blank canvas on which to express their brand personality, whether through a bright, eye-catching packaging for a product or a sleek, minimalist design for a luxury company. The utilization of these boxes encompasses a variety of functions, encompassing the safeguarding of the product during its transit and the augmentation of its visual attractiveness while displayed on the store shelf.

Custom Retail Boxes Simplify Processes and Cut Expenses

Businesses can eliminate wasted space and lessen the need for additional cushioning materials by customizing the packaging's dimensions to fit the product. Custom Retail Boxes will lower shipping costs and have a positive environmental impact. In addition, these boxes can be made with handles, dividers, or inserts to help with packing effectively and guarantee that the goods reach their destination undamaged and well-organized. Packaging becomes a pivotal function within the business, offering a purpose beyond mere containment of things. Businesses communicate their brand identity, values, and product attributes to their intended audience.

Custom Retail Packaging Support Their Environmental Credentials

Boxes can serve as an environmentally conscious alternative when there is a significant emphasis on environmental sustainability. When engaging in the production of Custom Retail Packaging, numerous firms opt for the utilization of eco-friendly materials and designs that align with their objective of reducing their carbon footprint. These boxes provide a sustainable choice for businesses aiming to enhance their environmental standing, as they can be adorned with water-based inks and fabricated using materials that are either recyclable or biodegradable. Within the realm of the purchasing experience, they assume a pivotal role in shaping consumer’s impressions, preferences, and their degree of loyalty towards a specific brand.

Create Brand Buzz by Incorporating Retail Packaging Boxes

Packaging may be vital in drawing in and keeping clients in a cutthroat industry. Customized, eye-catching Retail Packaging Boxes can make the unwrapping experience unforgettable and something buyers will probably post about on social media. Their creative potential allows an organic promotion to reach a wider audience and create brand buzz. Additionally, these boxes support marketing initiatives. The primary purpose of these boxes is to guarantee the intact arrival of the enclosed products to their designated location. This flexibility guarantees that goods are shown and safeguarded in the most excellent way feasible.

Retail Boxes Wholesale Showcase Products with Perfection

Boxes can also be customized to meet the unique requirements of various industries. For instance, in the food business, Retail Boxes Wholesale can be made to fit the needs of different items, such as robust canned foods or delicate pastries. The purpose of this packaging is to provide protection and maintain the integrity of the contents it encloses. The utilization of robust materials and meticulous design practices plays a crucial role in mitigating potential harm that may occur during the transportation and storage of goods. This, in turn, diminishes the probability of product returns and customer discontent.

Make the Shopping Experience Exciting with Printed Packaging Boxes

People can take advantage of the benefits of customized packaging to improve the display and safety of their things, whether it's for boxes for special occasions or shipping boxes for online sales. Printed Packaging Boxes will continue to be an essential instrument for delivering goods in a way that pleases the sight and the conscience as businesses change and customer expectations rise. In addition to fulfilling their protective function, packaging also serves as a potent marketing tool. The aesthetic elements, including the design, color, and graphics, of these boxes exert a substantial influence on consumer’s buying behavior.

Custom Packaging Boxes with Logo Make an Effective Product Display

Businesses are not the only ones who can use these boxes; individuals may also profit from this packing option. Custom Packaging Boxes with logo have grown to be an essential component of the packaging scene, giving both individuals and companies the chance to design packaging that suits their particular requirements and tastes. The various advantages these boxes provide, ranging from practicality and marketing to branding and sustainability, make them an Eco-friendly and memorable packaging option that is more effective. These boxes can be made to fit a variety of apparel goods, from bulky winter coats to delicate gowns, in the fashion industry.

Incorporate Modern Aesthetics within Customized Boxes with Logo

The way items remain packaged and delivered to customers has been revolutionized by this packaging, which is now an essential part of modern enterprises. Companies know that Customized Boxes with Logo is more than protection in today's cutthroat market. So, it's also an effective tool for marketing, branding, and crafting a distinctive consumer experience. A meticulously crafted box can captivate one's attention, effectively communicate product details, and instill a feeling of eager expectation. In a highly competitive retail setting, where numerous products compete for the attention of consumers, the visual appeal of a box can significantly impact consumer engagement.

Customized Packaging Boxes Remain Selective with Brand Colors

Companies invest in this packaging primarily to forge a distinctive brand character. A consumer and a product often come into touch for the first time at the package. Customized Packaging Boxes must successfully and fully communicate the brand's values, message, and image. With this packaging, businesses may select materials, colors, and logos that complement their brand identity, resulting in items that easily remain recognized on store shelves. The establishment of brand identity is an additional crucial element of this package. The entities above serve as an expansion of a brand's character and principles.

Attain Client Loyalty by Employing Custom Printed Packaging

Customers are more inclined to think the product inside is essential and worth the price when they see a well-made, premium package. Custom Printed Packaging might boost a business's profitability and support premium pricing. Furthermore, if consumers associate the brand with excellence, it may result in repeat business and client loyalty. For instance, a cosmetics company can offer customized packaging for its best-selling items, giving the purchasing experience more exclusivity. Additionally, its packaging raises a product's perceived worth. This lowers the company's carbon footprint and appeals to customers who care about the environment.

Product Boxes Wholesale Will Keep Products Budget-Friendly

Another critical component of this packaging is personalization. Product Boxes Wholesale will come by businesses for individual clients or niche markets. Customers and brands may develop a deeper bond due to this customization. The selection of colors, font, and graphics should be based on the brand's identity, establishing a unified and identifiable aesthetic throughout its goods. The establishment of a cohesive brand image engenders confidence and allegiance among consumers, hence increasing the likelihood of their preference for your offerings over those of rival companies.

Save Your Packaging Cost with Wholesale Retail Boxes

Packaging boxes guarantee that goods remain safe both in storage and during transportation. To lower the chance of damage or spoiling, businesses can select materials that offer the durability and protection required for the particular products they manufacture. Wholesale Retail Boxes can reduce the need for returns and replacements, making packaging essential to generating a great unboxing experience in the era of e-commerce. The utilization of custom box enables enterprises to establish a distinct presence within the market, setting themselves apart from other firms and fostering a lasting brand encounter.

Custom Boxes for Products Help Utilizing Recyclable and Biodegradable Materials

Packaging come to be environmentally friendly, satisfying the growing demand from customers for Eco-friendly goods and methods. Businesses can show that Custom Boxes for Products cares about the environment by reducing unnecessary packaging and utilizing recyclable or biodegradable materials. The incorporation of customization is a prominent trend within the realm of packaging. There is a growing recognition among businesses of the significance of customized packaging that aligns with their distinct brand identity and caters to the specific requirements of their intended consumer base.

Give Followers an Excellent Experience Using Retail Packaging Wholesale

Customer’s perception of the brand remains formed the instant they open a box. Sensitive touches like tissue paper, thank-you cards, or unusual opening techniques come in Retail Packaging Wholesale to excite the unwrapping experience and make it worthy of social media sharing. As consumers tell their followers about their excellent experiences, this may result in free word-of-mouth advertising. The inclusion of personalized messages or branding elements has the potential to establish a personal rapport with clients, augmenting their whole purchasing experience.

Custom Printed Boxes Adopt Safety Measures to Remain Durable

Boxes remain valuable in various industries and are not just for retail goods. Custom Printed Boxes, for instance, can guarantee that perishable goods stay fresh and tamper-evident in the food business. It can offer crucial details and safety measures to safeguard customers in the industry. These packaging options are flexible and may meet the unique requirements of any product or sector. The issue of sustainability is a continuously expanding concern within the realm of packaging. With the increasing awareness of environmental issues, customers are actively seeking products that align with their values.

Stay Adaptable in Today’s Market by Branding Custom Box Packaging

Beyond just keeping things safe, packaging serves as a multipurpose tool. Building brand identification, improving perceived value, customizing consumer experiences, and addressing environmental issues are all strategic advantages for organizations. When it comes to Custom Box Packaging, a company may stand out from the competition and win over customers in a world where options abound. However, they will influence how we engage with companies and products daily. It's more than just a box; in today's cutthroat market, it's a potent branding and marketing weapon that may determine a company's destiny.

Printed Custom Boxes Serve as a Tool for Product Creativity

Even though they are sometimes overlooked, boxes are essential to our daily lives. Printed Custom Boxes have several uses, including displaying branding and design and safeguarding goods during transit. It has become a necessary component of contemporary trade and society. They have a unique role in our culture and economy as a tool for creativity and a practical necessity. Companies that place a high emphasis on sustainability not only make a positive impact on the environment but also appeal to consumers who are environmentally aware and value their dedication to ethical conduct.

Arrive Safely on Final Destination through Wholesale Packaging with Logo

The purpose of this packaging is to protect the goods it contains. Wholesale Packaging with Logo acts as a barrier to protect sensitive products, perishable food products, and fragile glassware from the elements and potential harm. During transportation and handling, they protect goods from dust, moisture, and physical shocks. They guarantee they arrive at their destination undamaged and in perfect condition. The packaging also plays a crucial function in facilitating an unboxing experience. A significant number of consumers derive pleasure. They enhance a sense of anticipation by unveiling a meticulously created and aesthetically pleasing box.

Custom Made Boxes Wholesale Remain Responsive with Colors

Excellent packaging makes a big difference in marketing and branding initiatives. Custom Made Boxes Wholesale may be an effective tool in a congested marketplace to draw customers in and communicate a brand's personality. A brand's values, personality, and message come through the combination of colors, graphics, and text on a box. Customers can better identify and recall the brand thanks to its visual identity, which encourages repeat business and brand loyalty. At the same time, the popularity of eco-friendly packaging choices, using recycled materials, biodegradable inks, and minimalist designs, is rising.

Add Product Delight within Printed Packaging with Logo

Concise and easy-to-read information improves user experience and guarantees that buyers may choose products with knowledge. In addition to branding, Printed Packaging with Logo informs customers. Additionally, this packaging is essential to sustainability initiatives. The incorporation of various characteristics, such as personalized inserts, delicate tissue paper, and branded stickers, can achieve the enhancement of this experience. A meticulously designed unpacking experience has the potential to have a lasting impact on customers. They resulted in favorable reviews and increased brand exposure through social media sharing.

Wholesale Retail Packaging Boxes Set Preference to Recyclable Content

There has been a growing adoption of environmentally sustainable packaging solutions by businesses. However, they drive by the increasing prominence of environmental concerns. Wholesale Retail Packaging Boxes are designed to mitigate the negative environmental impacts of materials by utilizing recyclable components. Advancements in design and materials have facilitated the development of sustainable packaging solutions. They effectively mitigate trash generation and encourage responsible disposal practices. Packaging is crucial in modern commerce, surpassing its traditional function as simple receptacles. They often play a crucial role in enabling the initial physical engagement that internet consumers commonly have with an organization.

Heighten the Pleasure Using Printed Packaging Boxes with Logo

In this era, packaging has acquired heightened importance. Boxes are frequently the first in-person encounters clients have with a brand's items due to the increase in online shopping. Printed Packaging Boxes with Logo has become even more critical in the age of online shopping. They must, therefore, be both aesthetically beautiful and practical. Businesses are investing in distinctive and imaginative packaging designs that heighten the pleasure and anticipation of getting a product as unboxing experiences have grown in popularity. On the outside of boxes, labels, product descriptions, and usage guidelines give customers important information about the goods within.

Printed Boxes with Logo Turn into a Stackable Option

Box sizes and shapes that are standard allow firms to maximize warehouse storage space and expedite shipping procedures. As a result, this efficiency results in lower costs and quicker delivery times for customers. Additionally, the overall effectiveness of supply chains is enhanced by Printed Boxes with Logo. They are perfect for storage and transit since they are stackable and manageable. Consequently, businesses must consider the design and quality of their packaging diligently. Thus, they provide a favorable initial perception and foster customer loyalty. The impact of the design, personalization, and sustainability of these boxes on consumer’s views and decisions is significant.

Our agents are here in live chat around the clock for your assistance. Our customer support is always at your service, so you can quickly get the correct information. Call (281) 393-8119 or complete the requirements form. Any comments or other inquiries can be sent to us via email at support@custompackagingpro.com. We will be happy to assist you. You can quickly obtain any of these boxes based on your ideas at the retail level. Packaging Pro offers stylish packaging box designs and high-quality customized packaging at discounted prices.

Why choose us?

Choose us for unrivaled knowledge and commitment. Our skilled team is dedicated to providing outstanding results. Your pleasure is our first priority, and we provide customized solutions and excellent service. So, we distinguish ourselves as the reliable option for your needs thanks to our reputation for quality. Our top priority is your success.

A quality product needs quality packaging. Custom Packaging pro is the right place to have the highest quality custom boxes which speak for itself. By using the finest material and latest packaging tools, we meet the quality standard of the packaging market. From custom retail packaging to wholesale custom packaging, quality is guaranteed at every step and in every box.

CPP offers nothing but the best. At our place, you will find the desired information in no time with lots of packaging options and possibilities. No matter what you are looking for, whether it is custom printed boxes or cheap custom boxes or custom retail packaging, we have got you covered. We can go the extra mile for you to meet your needs with versatile and flexible packaging solutions.

Our packaging solutions are not only reserved only for big retailers. We work for everyone by providing custom packaging for small businesses. The main idea is to encourage brands to convey their brand image with custom packaging and that too at an affordable and competitive price. We will customize your packaging in a budget-smart way to meet your brand needs. We also offer custom wholesale boxes for startups and small brands.

Customized packaging is what a brand needs to target audience and convey the brand story. We believe that the end product should be distinguishable and better than your imagination. With our endless customization options, you will see how we turn your concept into a fully customized custom printed box. With the help of a variety of colors, sizes, shapes, printing options, embossing, coating we aim to deliver what you exactly envisioned.

We only use the material that is environmental-friendly. We use the most excellent biodegradable cardboard material to fulfill the corporate social responsibility in the society.

Our whole shipment delivery process is simple, hassle-free, convenient and always on time. We have a team of dedicated and devoted workers who work efficiently to meet the targeted deadlines without setting on quality. We offer the fastest turnaround time to WOW clients by delivering the order in the promised time. We also try to provide the order before time to get early feedback and make the required changes as per your needs.

Custom Packaging pro believes in excellent and responsive customer service. We have a 24/7 Online Chat / Phone support to help our clients. Our customer service team is always ready to help you with custom boxes and custom packaging queries. You can talk to our dedicated custom packaging experts for your packaging needs and solutions.

Testimonials

Clients Feedback

Clients Feedback

-

Huge shouttttt!!!! My boxes are arrived and the quality is exactly what I wanted and CustomPackagingPro worked well with my design expectations. I am a graphic designer and I was very specific about the 'look and feel' of my boxes. CustomPackagingPro team communication skills are very good, and I felt I was always 'in the loop' when it came to updates and my requests. I would highly recommend to everyone!

Alina Berry

-

Jeff is amazing and it was awesome doing business here. Very competitive pricing and super easy to work with! I appreciate that when issues came up (caused by me) Jeff and his team were willing to help out and made the correct edits. - highly recommend!

Kelly Green

Our print experts are happy to provide you with a Custom Quote for just about anything you can dream up. It will just take your 5 minutes.

Request Custom QuoteRequest Call Back

Please enter phone number and we will get back to you shortly OR Call (346) 396 -3327